In today’s fast-evolving industrial and consumer markets, nano double-sided tape has emerged as a revolutionary bonding solution that combines advanced material science with exceptional practical performance.

Comprehensive Guide to Hot Melt Adhesive Tape: Applications, Benefits, and Innovations

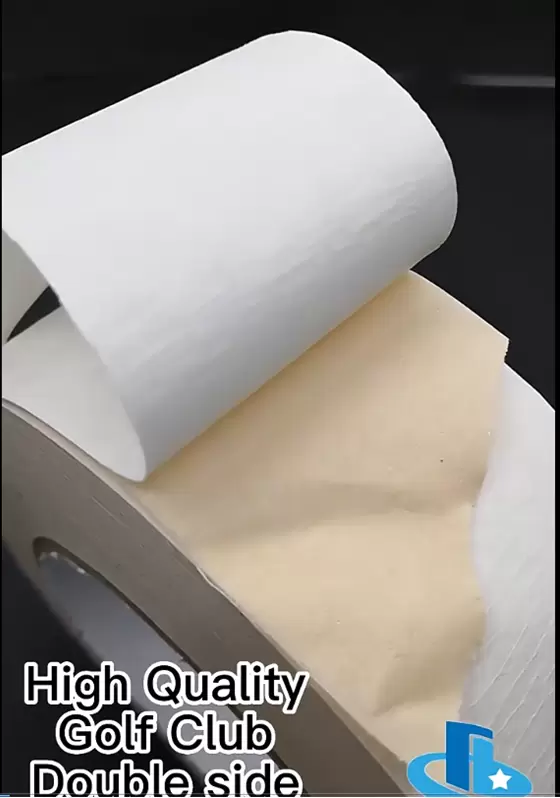

In the modern manufacturing and packaging landscape, hot melt adhesive tape has emerged as an indispensable tool across multiple industries. Known for its strong bonding properties, quick setting time, and versatility, this adhesive solution is used extensively in electronics, automotive manufacturing, furniture production, packaging, and more. At Xingda New Material, we specialize in supplying high-quality hot melt adhesive tape, designed to meet the rigorous demands of professional and industrial applications. This article explores the fundamentals of hot melt adhesive tape, its advantages, applications, types, and the future of adhesive technologies.

What is Hot Melt Adhesive Tape?

Hot melt adhesive tape is a type of pressure-sensitive tape coated with a thermoplastic adhesive that becomes tacky when heated. Unlike traditional water-based adhesives, hot melt adhesives do not require long drying times. Instead, the adhesive softens upon heating, allowing immediate bonding upon cooling and pressure application. This unique property makes hot melt adhesive tape particularly suitable for high-speed production lines and applications where rapid assembly is critical.

The adhesive composition typically includes ethylene-vinyl acetate (EVA), polyolefins, or other synthetic polymers. These materials are selected for their excellent adhesion to diverse surfaces such as plastics, metals, wood, and paper. Xingda New Material ensures that all our hot melt adhesive tapes use premium-quality polymers, providing consistent performance under varied environmental conditions.

Key Advantages of Hot Melt Adhesive Tape

The popularity of hot melt adhesive tape is largely driven by its numerous advantages over traditional adhesive solutions. Some of the key benefits include:

Fast Bonding: The thermoplastic nature of the adhesive allows it to bond almost instantly upon cooling, significantly reducing production time.

Strong Adhesion: Hot melt adhesive tapes provide robust bonding across different substrates, including metals, plastics, and coated surfaces.

Temperature Resistance: High-quality hot melt adhesive tapes maintain their adhesion properties across a wide temperature range, making them suitable for industrial environments.

No Solvents Required: Unlike solvent-based adhesives, hot melt adhesive tape is environmentally friendly and safe for workers since it contains no harmful chemicals.

Versatility: These tapes can be customized in thickness, width, and adhesive strength, making them suitable for diverse industrial and household applications.

Clean Application: Hot melt adhesive tape provides a clean, precise bonding solution without messy drips or spills.

By leveraging these advantages, companies can streamline operations and ensure a higher level of reliability in bonding applications.

Industrial Applications of Hot Melt Adhesive Tape

Hot melt adhesive tape has a wide range of applications across multiple industries. Its flexibility and performance have made it a preferred solution in both high-tech and traditional manufacturing environments.

1. Electronics Manufacturing

In electronics assembly, precision and reliability are paramount. Hot melt adhesive tapes are used to:

Bond components on printed circuit boards (PCBs)

Secure wires and cables

Protect sensitive areas during soldering or coating processes

The high thermal resistance and electrical insulation properties of these tapes make them ideal for electronic applications. Xingda New Material provides tapes with tailored adhesive strengths suitable for intricate electronic assembly.

2. Automotive Industry

The automotive industry relies heavily on hot melt adhesive tape for:

Attaching trims and emblems

Securing interior panels and components

Sealing lightweight composite parts

Automobile manufacturers benefit from the strong adhesion and durability of hot melt adhesive tape, particularly in vehicles exposed to vibration and temperature fluctuations.

3. Packaging Solutions

Hot melt adhesive tape has revolutionized the packaging sector by offering faster and more reliable sealing options. Its applications include:

Sealing cartons and boxes for logistics

Attaching labels and protective films

Securing products for shipment

The quick bonding property of hot melt adhesive tape improves operational efficiency in high-volume packaging environments.

4. Furniture and Woodworking

In furniture production, hot melt adhesive tape is used for:

Laminating wood panels

Bonding veneers

Attaching decorative trims

The strong bond and clean application ensure high-quality finishes, making hot melt adhesive tape a preferred choice for furniture manufacturers.

5. Medical and Hygiene Products

Certain grades of hot melt adhesive tape are suitable for medical and hygiene applications due to their non-toxic composition. Applications include:

Securing medical devices

Manufacturing disposable hygiene products

Attaching protective films

In these applications, the tape must meet strict safety and quality standards, which Xingda New Material ensures through rigorous testing.

Types of Hot Melt Adhesive Tape

Understanding the different types of hot melt adhesive tape is essential for selecting the right product for specific applications. The most common categories include:

1. EVA-Based Hot Melt Adhesive Tape

Ethylene-vinyl acetate (EVA) provides excellent adhesion to plastics, metals, and paper. EVA-based tapes are widely used in electronics and packaging industries for their high bonding strength and flexibility.

2. Polyolefin-Based Tape

Polyolefin adhesives offer superior heat resistance and durability, making them ideal for automotive and industrial applications. These tapes maintain adhesion even under extreme temperatures and mechanical stress.

3. Specialty Formulations

Some hot melt adhesive tapes are formulated with additives to provide:

Flame retardancy

Electrical insulation

Moisture resistance

UV protection

Xingda New Material offers customized formulations to meet the specific requirements of clients across industries.

Choosing the Right Hot Melt Adhesive Tape

Selecting the correct hot melt adhesive tape requires careful consideration of several factors:

Substrate Compatibility: The tape should adhere strongly to the surface material, whether it is plastic, metal, wood, or paper.

Temperature Requirements: Consider the environmental and operational temperatures to ensure the adhesive maintains performance.

Thickness and Width: Different applications require different tape dimensions for optimal performance.

Bond Strength: Evaluate the required shear and peel strength depending on the load and stress the tape must withstand.

Application Method: Hot melt adhesive tape can be applied manually or with automated machinery; the choice affects speed and precision.

Xingda New Material provides consultation services to help clients choose the optimal tape based on these parameters, ensuring reliable performance in every application.

Innovations in Hot Melt Adhesive Tape Technology

The hot melt adhesive tape industry has witnessed significant technological advancements over the past decade. Modern innovations focus on improving bonding efficiency, environmental sustainability, and versatility. Key trends include:

Bio-based Adhesives: Manufacturers are exploring plant-derived polymers to reduce environmental impact.

High-Temperature Resistance: New formulations withstand extreme heat for automotive, aerospace, and electronics applications.

Multi-Surface Adhesion: Advanced tapes can bond difficult surfaces such as low-energy plastics without primers.

Automated Application Systems: Innovations in tape dispensing machinery improve speed, accuracy, and repeatability on production lines.

By staying at the forefront of these innovations, Xingda New Material ensures that our clients benefit from the latest advancements in adhesive technology.

Quality Standards and Testing

Ensuring the reliability of hot melt adhesive tape requires rigorous testing and adherence to international quality standards. Key performance tests include:

Peel strength tests

Shear adhesion tests

Temperature and humidity resistance tests

Aging and durability tests

Xingda New Material conducts comprehensive quality control to verify that every roll of tape meets strict performance specifications. This commitment ensures that our hot melt adhesive tape consistently delivers strong, durable bonds in all applications.

Environmental and Safety Considerations

Hot melt adhesive tapes are inherently more environmentally friendly than solvent-based adhesives, as they do not emit volatile organic compounds (VOCs). Additionally, the lack of hazardous solvents reduces health risks for workers handling the tape. However, proper usage guidelines must be followed:

Avoid overheating the adhesive beyond recommended temperatures.

Store tapes in cool, dry conditions to prevent premature aging.

Follow industrial safety standards for automated tape application machinery.

Xingda New Material emphasizes safety and sustainability while delivering high-performance hot melt adhesive tape solutions.

Why Choose Xingda New Material for Hot Melt Adhesive Tape

Xingda New Material is a leading supplier of high-quality hot melt adhesive tape. Our commitment to innovation, quality, and customer service sets us apart. Benefits of working with us include:

Custom formulations to suit unique applications

Extensive inventory for quick delivery

Technical support and consultation services

Compliance with international quality and safety standards

Whether you are in electronics, automotive, packaging, or any other industry, Xingda New Material has the hot melt adhesive tape solution that meets your needs.

Conclusion

The importance of hot melt adhesive tape in modern manufacturing and industrial applications cannot be overstated. Its rapid bonding, strong adhesion, versatility, and environmentally friendly nature make it an essential material across industries. At Xingda New Material, we supply premium hot melt adhesive tapes tailored to meet the demanding requirements of professional and industrial applications. By choosing our products, companies gain a reliable, high-performance adhesive solution that enhances efficiency and quality.