Reusable Nano Tape has rapidly emerged as a revolutionary adhesive solution in both consumer and industrial markets, fundamentally changing how people fix, mount, organize, and display items without permanent damage.

Pressure Sensitive Adhesive Tape Manufacturer – Xingda New Material

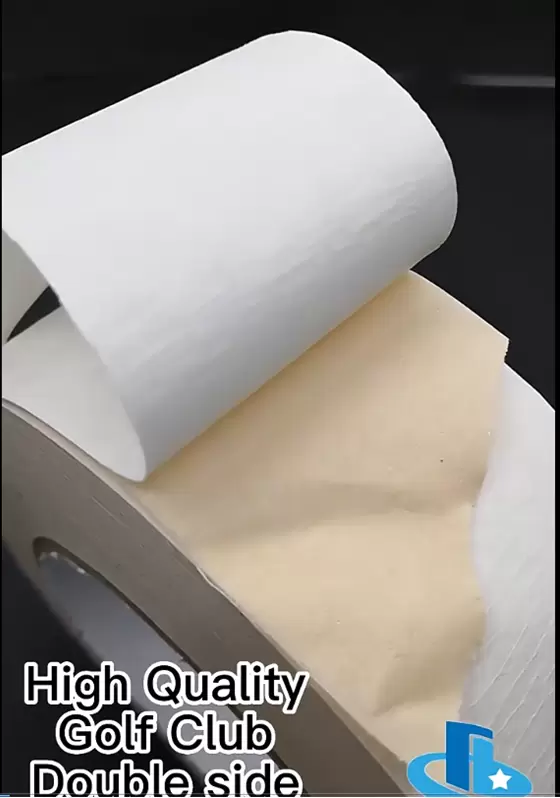

In today’s fast-evolving industrial and commercial landscape, pressure sensitive adhesive tape has become an indispensable bonding solution across countless sectors. From automotive assembly and electronics manufacturing to packaging, construction, healthcare, and household applications, the demand for reliable and high-performance pressure sensitive adhesive tape continues to expand. Xingda New Material, as a professional supplier of pressure-sensitive bonding solutions, is dedicated to delivering advanced adhesive technologies that meet the evolving needs of global industries.

This comprehensive guide explores the composition, performance characteristics, manufacturing processes, application fields, and technological innovations behind pressure sensitive adhesive tape, while highlighting how Xingda New Material ensures quality, durability, and customization for every customer.

Understanding Pressure Sensitive Adhesive Tape

A pressure sensitive adhesive tape is a type of adhesive product that bonds to surfaces upon the application of light pressure, without requiring water, solvent, or heat activation. Unlike traditional glues that rely on chemical curing or thermal activation, pressure sensitive adhesive tape forms an immediate bond through viscoelastic properties engineered into the adhesive layer.

The structure of a typical pressure sensitive adhesive tape consists of three primary components:

Backing Material – Film, paper, foam, cloth, or specialty substrates

Adhesive Layer – Acrylic, rubber-based, silicone, or hybrid systems

Release Liner (optional) – Protects adhesive until application

At Xingda New Material, every pressure sensitive adhesive tape is designed with precision to balance adhesion, cohesion, tack, shear strength, and environmental resistance.

Key Performance Characteristics of Pressure Sensitive Adhesive Tape

The performance of pressure sensitive adhesive tape depends on several critical physical and chemical properties:

1. Tack

Tack refers to the initial stickiness of a pressure sensitive adhesive tape when light pressure is applied. High tack ensures quick bonding, which is essential for fast-paced industrial assembly lines.

2. Peel Strength

Peel strength measures the force required to remove pressure sensitive adhesive tape from a substrate. Applications such as automotive trim bonding or structural mounting require high peel performance.

3. Shear Resistance

Shear strength determines how well pressure sensitive adhesive tape withstands sustained loads over time. For mounting applications and heavy-duty bonding, high shear resistance is critical.

4. Temperature Resistance

Industrial environments often demand pressure sensitive adhesive tape that can endure high heat or freezing conditions without adhesive failure.

5. Chemical and UV Resistance

Outdoor and automotive uses require pressure sensitive adhesive tape that resists UV degradation, moisture, solvents, and chemicals.

Xingda New Material rigorously tests each batch of pressure sensitive adhesive tape to ensure compliance with international performance standards.

Types of Pressure Sensitive Adhesive Tape

Different industries require different formulations of pressure sensitive adhesive tape. Below are common types supplied by Xingda New Material:

Acrylic Pressure Sensitive Adhesive Tape

Acrylic-based pressure sensitive adhesive tape offers excellent UV stability, long-term aging resistance, and strong adhesion to various substrates. It is widely used in electronics, automotive, and construction sectors.

Rubber-Based Pressure Sensitive Adhesive Tape

Rubber adhesive systems provide high initial tack and strong adhesion to low-energy surfaces. This type of pressure sensitive adhesive tape is commonly used in packaging and general-purpose bonding.

Silicone Pressure Sensitive Adhesive Tape

For high-temperature or specialty applications, silicone-based pressure sensitive adhesive tape delivers exceptional heat resistance and chemical stability.

Foam Pressure Sensitive Adhesive Tape

Foam-backed pressure sensitive adhesive tape offers cushioning, sealing, and vibration damping, making it ideal for automotive and HVAC industries.

Each category of pressure sensitive adhesive tape can be customized in thickness, width, adhesive formulation, and backing material.

Industrial Applications of Pressure Sensitive Adhesive Tape

The versatility of pressure sensitive adhesive tape allows it to serve multiple industries effectively.

Automotive Industry

Modern vehicles rely heavily on pressure sensitive adhesive tape for bonding trim, emblems, sensors, insulation materials, and structural components. Compared to mechanical fasteners, pressure sensitive adhesive tape reduces weight and enhances design flexibility.

Electronics Manufacturing

In electronics, pressure sensitive adhesive tape is used for component mounting, insulation, shielding, and display assembly. Precision die-cut pressure sensitive adhesive tape ensures consistent bonding in compact devices.

Construction and Building

Construction professionals utilize pressure sensitive adhesive tape for sealing, insulation, flooring installation, and facade bonding. Durable acrylic systems provide long-term weather resistance.

Packaging Industry

Packaging operations depend on pressure sensitive adhesive tape for carton sealing, labeling, and protective wrapping. Reliable adhesion ensures product safety during transportation.

Medical Sector

Medical-grade pressure sensitive adhesive tape is formulated for skin contact, offering breathability, hypoallergenic properties, and secure fixation.

At Xingda New Material, we analyze each industry’s requirements before recommending the most suitable pressure sensitive adhesive tape solution.

Manufacturing Process of Pressure Sensitive Adhesive Tape

The production of high-quality pressure sensitive adhesive tape requires advanced coating and curing technologies. Xingda New Material employs state-of-the-art equipment to ensure consistency and precision.

Adhesive Formulation

The performance of pressure sensitive adhesive tape begins with precise polymer formulation. Raw materials are carefully blended to achieve optimal viscosity, tack, and cohesion.

Coating Process

Adhesive is coated onto the selected backing material using controlled coating lines. Uniform thickness is essential for consistent performance of pressure sensitive adhesive tape.

Drying and Curing

Depending on the adhesive system, solvent evaporation or UV curing stabilizes the pressure sensitive adhesive tape before further processing.

Slitting and Die-Cutting

Large rolls of pressure sensitive adhesive tape are slit into customized widths or die-cut into specific shapes based on customer requirements.

Quality Inspection

Each roll of pressure sensitive adhesive tape undergoes strict quality checks, including adhesion tests, tensile strength measurements, and environmental resistance verification.

Advantages of Pressure Sensitive Adhesive Tape Over Traditional Bonding

Choosing pressure sensitive adhesive tape offers numerous advantages compared to screws, rivets, and liquid adhesives:

Immediate bonding without curing time

Clean and residue-free application

Uniform stress distribution

Lightweight design compatibility

Noise and vibration reduction

Corrosion prevention

Increased production efficiency

By replacing mechanical fasteners with pressure sensitive adhesive tape, manufacturers can streamline assembly processes and enhance product aesthetics.

Customization Capabilities at Xingda New Material

Every industry faces unique bonding challenges. Xingda New Material provides fully customizable pressure sensitive adhesive tape solutions, including:

Custom adhesive formulations

Multiple backing materials

Thickness and width adjustments

Die-cut shapes and kiss-cut formats

High-temperature resistant variants

Waterproof and weatherproof options

Our R&D team collaborates closely with clients to develop tailored pressure sensitive adhesive tape that aligns with performance specifications and budget requirements.

Quality Control and Certifications

Maintaining superior quality is central to every pressure sensitive adhesive tape supplied by Xingda New Material. Our production facilities implement strict quality management systems, including:

ISO-compliant manufacturing processes

Batch traceability systems

Laboratory-based adhesion testing

Environmental simulation testing

Raw material verification protocols

These procedures ensure that each pressure sensitive adhesive tape delivers consistent performance in demanding applications.

Environmental Responsibility and Sustainable Adhesive Solutions

As environmental awareness grows, the adhesive industry is evolving toward sustainable materials. Xingda New Material invests in eco-friendly technologies to develop low-VOC and solvent-free pressure sensitive adhesive tape options.

We focus on:

Water-based acrylic systems

Recyclable backing materials

Reduced solvent emissions

Energy-efficient production lines

By offering sustainable pressure sensitive adhesive tape, we help customers meet environmental regulations and corporate sustainability goals.

Research and Development Innovation

Technological innovation drives the advancement of pressure sensitive adhesive tape. Xingda New Material continuously invests in R&D to enhance:

High-temperature resistance

Low-surface-energy bonding capability

Flame-retardant performance

Conductive and insulating properties

Anti-static adhesive systems

Through ongoing material science research, we ensure that our pressure sensitive adhesive tape remains competitive in global markets.

Why Choose Xingda New Material?

Selecting the right supplier for pressure sensitive adhesive tape is critical to product performance and operational efficiency. Xingda New Material stands out because of:

Extensive industry experience

Advanced production equipment

Strong R&D capabilities

Strict quality control systems

Customizable solutions

Global export experience

Responsive technical support

Our commitment is to provide reliable, cost-effective, and innovative pressure sensitive adhesive tape that supports long-term business growth.

Global Market Trends in Pressure Sensitive Adhesive Tape

The global demand for pressure sensitive adhesive tape continues to rise due to automation, lightweight vehicle design, renewable energy expansion, and electronics miniaturization. Emerging technologies such as electric vehicles and smart devices rely increasingly on advanced pressure sensitive adhesive tape solutions.

Xingda New Material remains aligned with these trends by developing high-performance tapes that meet evolving industry standards.

Conclusion

The role of pressure sensitive adhesive tape in modern manufacturing and industrial applications cannot be overstated. From structural bonding and insulation to packaging and medical fixation, this versatile adhesive solution continues to redefine efficiency and reliability.

Xingda New Material is dedicated to supplying premium pressure sensitive adhesive tape that meets global quality standards and diverse application requirements. Through advanced manufacturing, strict quality assurance, continuous innovation, and customer-focused service, we provide adhesive solutions that deliver long-term value.

If you are seeking a dependable supplier of high-performance pressure sensitive adhesive tape, Xingda New Material is ready to support your business with customized, cost-effective, and technologically advanced bonding solutions.