Athletic tape is a cornerstone in sports medicine, physical therapy, and athletic training, serving a critical role in injury prevention, rehabilitation, and performance support.

The Comprehensive Guide to Waterproof Acrylic Foam Tape: Performance, Applications, and Benefits

In the modern manufacturing and construction landscape, adhesive solutions play a crucial role in enhancing structural integrity, ensuring waterproofing, and providing long-lasting bonding. Among these solutions, waterproof acrylic foam tape has emerged as a versatile and high-performance choice for industries ranging from automotive and electronics to construction and signage. Manufactured with precision and engineered for durability, this tape offers unique properties that make it indispensable in applications requiring strong adhesion, flexibility, and resistance to environmental stress.

What is Waterproof Acrylic Foam Tape?

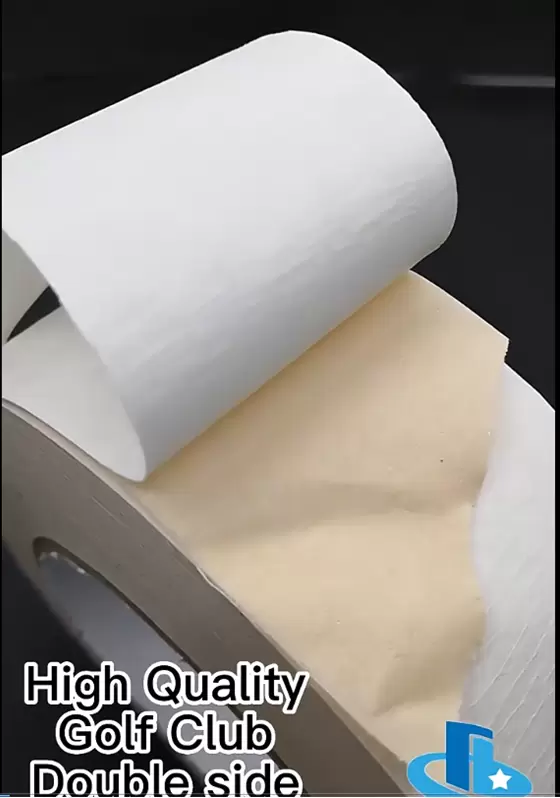

Waterproof acrylic foam tape is a type of pressure-sensitive adhesive tape composed of a closed-cell acrylic foam core coated on both sides with high-performance adhesive. The foam structure provides cushioning and gap-filling properties, while the acrylic adhesive ensures strong bonding to a wide range of substrates, including metals, plastics, glass, and painted surfaces. The waterproof nature of the tape makes it resistant to moisture, humidity, and other environmental factors, which is essential for applications exposed to outdoor or harsh conditions.

Unlike ordinary adhesive tapes, waterproof acrylic foam tape offers superior dimensional stability, high shear strength, and excellent resistance to UV rays, temperature variations, and chemicals. This makes it ideal for applications where reliability and longevity are non-negotiable.

Key Features of Waterproof Acrylic Foam Tape

High Adhesion Strength: The acrylic adhesive ensures strong initial tack and long-term adhesion to multiple surfaces, including smooth, rough, or curved surfaces.

Waterproof and Weather-Resistant: Its closed-cell foam structure prevents water ingress and maintains adhesive integrity in humid or wet conditions.

Excellent Cushioning: The foam core provides vibration damping and shock absorption, protecting sensitive components.

UV and Chemical Resistance: Suitable for outdoor applications as it withstands UV degradation and resists chemicals like oils, detergents, and solvents.

Temperature Tolerance: Can operate effectively in temperatures ranging from -40°C to 120°C, depending on the product specification.

Conformability: Easily conforms to irregular surfaces, making it perfect for automotive trims, electronic devices, and uneven substrates.

By combining these features, waterproof acrylic foam tape stands out as a multifunctional adhesive solution for demanding applications.

Manufacturing Process of Waterproof Acrylic Foam Tape

The production of waterproof acrylic foam tape involves multiple advanced processes to ensure consistent quality and performance. Understanding the manufacturing process highlights why this tape is preferred across industries.

Foam Formation: High-quality acrylic polymer is processed to create a closed-cell foam with the desired density and thickness. The closed-cell structure is crucial for waterproofing.

Adhesive Coating: Both sides of the foam are coated with a pressure-sensitive acrylic adhesive. This step ensures uniform adhesive thickness and strong surface bonding.

Curing and Laminating: The tape undergoes controlled curing to enhance adhesion properties. Lamination may also be applied to improve surface smoothness and durability.

Slitting and Packaging: Finally, the tape is cut into rolls or sheets of various widths and lengths, tailored to industry specifications. Each roll is inspected for quality, ensuring consistent performance.

The precision in this process guarantees that the final product delivers high adhesion, waterproofing, and long-term reliability.

Applications of Waterproof Acrylic Foam Tape

Waterproof acrylic foam tape is widely used across multiple industries due to its adaptability and performance. Below are some of the most common applications:

1. Automotive Industry

The automotive sector relies heavily on waterproof acrylic foam tape for interior and exterior applications. These include:

Attaching trim and moldings: The tape adheres to irregular surfaces and curved components without the need for mechanical fasteners.

Sealing windows and sunroofs: Provides waterproof sealing to prevent leaks and water ingress.

Mounting badges and emblems: Ensures secure attachment even under high-temperature conditions and vehicle vibrations.

Noise, Vibration, and Harshness (NVH) damping: The foam’s cushioning properties reduce vibrations and improve driving comfort.

Automakers increasingly prefer adhesive solutions like waterproof acrylic foam tape over traditional fasteners to streamline assembly, reduce weight, and enhance aesthetic appeal.

2. Construction and Architectural Applications

In construction, waterproof acrylic foam tape plays a critical role in sealing and bonding applications:

Window and door installation: Ensures airtight and waterproof seals between frames and building structures.

Facade bonding: Secures exterior panels, signage, and decorative elements without visible screws or mechanical fixings.

Roofing applications: Provides water-resistant sealing for metal sheets, skylights, and other roofing components.

The tape’s ability to conform to uneven surfaces and resist weather conditions makes it ideal for long-term outdoor use.

3. Electronics and Electrical Industry

For electronics manufacturers, waterproof acrylic foam tape offers precision bonding and protection:

Mounting screens and displays: Provides cushioning and adhesion for touch panels and LCD screens.

Securing components: Holds sensitive electronic parts in place while providing shock absorption.

Waterproofing enclosures: Ensures electronic devices remain protected against moisture and humidity.

Its combination of adhesion strength, flexibility, and waterproofing is critical in maintaining product reliability.

4. Signage and Advertising

In the signage industry, waterproof acrylic foam tape ensures durability and clean installation:

Mounting outdoor signs: Strong adhesion prevents peeling in extreme weather.

Attaching decorative elements: Allows precise positioning without damaging surfaces.

Temporary or permanent fixtures: Can be used for installations that require either long-term or removable bonding solutions.

5. Other Industrial Applications

Other notable applications include:

HVAC systems for sealing ducts

Marine applications for water-resistant bonding

Furniture assembly for invisible attachment of components

Automotive lighting and reflectors

Across these applications, waterproof acrylic foam tape consistently provides strong adhesion, durability, and waterproofing.

Benefits of Using Waterproof Acrylic Foam Tape

The advantages of using waterproof acrylic foam tape extend beyond adhesion and waterproofing. Here are the key benefits:

Eliminates Mechanical Fasteners: Reduces the need for screws, bolts, or rivets, saving time and cost in assembly.

Aesthetic Enhancement: Creates clean, smooth surfaces without visible fasteners or blemishes.

Durability: Maintains adhesion and performance over years, even in challenging environmental conditions.

Flexibility: Conforms to complex geometries, curves, and uneven surfaces.

Cost-Effective: Minimizes labor costs and reduces material usage compared to traditional bonding methods.

Environmental Resistance: Resists water, UV, chemicals, and temperature fluctuations, making it suitable for outdoor use.

By combining these benefits, manufacturers, builders, and designers gain both functional and economic advantages.

Choosing the Right Waterproof Acrylic Foam Tape

Selecting the correct waterproof acrylic foam tape is crucial for ensuring optimal performance. Factors to consider include:

Adhesive Type: Choose the adhesive formulation compatible with your substrate material. Some adhesives perform better on metals, while others excel on plastics or painted surfaces.

Foam Thickness and Density: Thicker foams provide better gap filling and cushioning, while higher density foams offer increased shear strength.

Temperature Resistance: Ensure the tape can withstand operating temperatures of the intended environment.

UV and Weather Resistance: For outdoor applications, select a tape resistant to UV degradation and extreme weather.

Application Method: Pressure-sensitive tapes require proper surface preparation to achieve maximum bonding strength.

Consulting with suppliers like Xingda New Material ensures the correct specification for your project requirements.

Surface Preparation for Optimal Adhesion

Proper surface preparation is essential for waterproof acrylic foam tape to achieve its maximum performance:

Cleaning: Remove dust, dirt, oil, and grease from the surface. Use alcohol-based cleaners or mild detergents.

Drying: Ensure the surface is completely dry before application. Moisture can compromise adhesion.

Smoothing: For rough surfaces, sanding may be necessary to improve contact with the adhesive.

Temperature Consideration: Apply the tape within the recommended temperature range to achieve the best tack and bonding.

Following these preparation steps ensures long-term reliability and waterproofing.

Installation Tips for Waterproof Acrylic Foam Tape

Measure and cut the tape accurately according to your project requirements.

Apply firm, even pressure along the tape to enhance adhesive contact.

Allow a curing period for maximum bond strength, typically 24 to 72 hours depending on application.

Avoid stretching the tape during application, as this may compromise adhesion.

By adhering to these guidelines, users can achieve consistent results across multiple applications.

Industry Standards and Compliance

High-quality waterproof acrylic foam tape complies with international standards for safety, environmental impact, and performance. These standards may include:

ISO certifications for quality management (ISO 9001)

RoHS compliance for environmentally safe materials

ASTM standards for adhesive strength, shear, and peel properties

Choosing certified products ensures reliable performance and adherence to industry regulations.

Future Trends in Waterproof Acrylic Foam Tape

The demand for waterproof acrylic foam tape is expected to grow as industries increasingly prioritize lightweight construction, aesthetic design, and environmental resilience. Future trends include:

Eco-friendly formulations: Development of adhesives with lower VOC content and recyclable foam cores.

Enhanced temperature and chemical resistance: Catering to extreme automotive and industrial applications.

Integration with smart materials: Combining foam tapes with sensors or conductive layers for electronic applications.

Customized tape solutions: Tailored thickness, color, and adhesive properties for specialized projects.

As technology evolves, waterproof acrylic foam tape continues to adapt, offering even greater versatility and performance.

Why Choose Xingda New Material for Waterproof Acrylic Foam Tape

Xingda New Material is a leading supplier of high-quality waterproof acrylic foam tape. Our commitment to innovation, quality, and customer satisfaction ensures that clients receive products that meet and exceed industry standards. Key reasons to choose us include:

Wide Product Range: Various thicknesses, densities, and adhesive types for diverse applications.

Reliable Performance: Consistently high adhesion, waterproofing, and durability.

Custom Solutions: Tailored products to meet unique industrial requirements.

Technical Support: Expert guidance for proper selection, application, and installation.

Partnering with Xingda New Material guarantees access to advanced adhesive solutions backed by professional service and quality assurance.

Conclusion

Waterproof acrylic foam tape has revolutionized bonding and sealing solutions across industries. Its combination of strong adhesion, waterproofing, cushioning, and resistance to environmental stress makes it an essential material for automotive, construction, electronics, and signage applications. By choosing high-quality products from reputable suppliers like Xingda New Material, manufacturers and designers can achieve reliable performance, aesthetic appeal, and cost-effective solutions.

Whether you are sealing a window, mounting automotive trims, or installing sensitive electronic components, waterproof acrylic foam tape offers the durability and versatility required for modern applications.

For high-performance waterproof acrylic foam tape tailored to your industry needs, contact Xingda New Material today. Our experts are ready to help you select the perfect tape solution for your project.